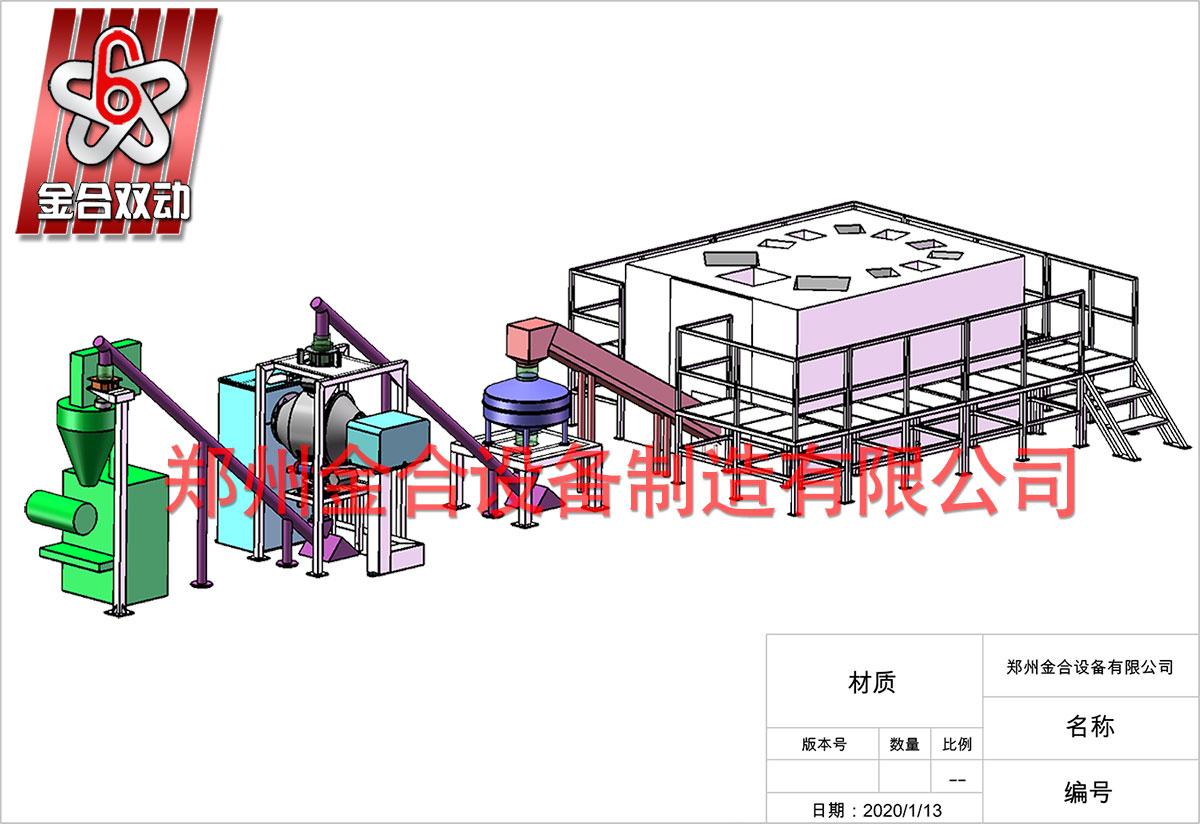

JHL200 full auto powder weighing mixing packing line

Description of the JHL200 line:

Production process: feeding-weighing-feeding-vibration screening-loading-mixing-discharging-gold

detection-packaging

1, Feeding: the feeding bin is divided into three main material bins and eight trace element bins, the

main material bin and the trace element bin are put into the buffer stock bin for more input, The

amount of materials used is convenient for subsequent weighing, and the three main materials are

used for sharing one weighing bin, three materials are individually weighed, and 8 microamounts

The element grains share one weighing bin, and 8 kinds of materials are individually weighed one

by one;

2. Weighing: The materials are weighed one by one in the weighing bin according to the set weight

(1 material weighing is completed and released the next material is referred to as the next material);

3, Feeding: after the material is weighed, the belt conveyor is operated, the mixer is finished, the feeding

opening is opened, the vibrating screen is operated, the discharge port of the weighing bin is automatically

opened, and the materials enter the belt conveyor, and the materials to be mixed enter the vibrating screen

through the conveyor;

4. Vibration screening: material is screened by the material passing through the belt conveyor to the vibrating

screen;

5. Feeding: the material is screened by a vibrating screen and then directly enters a screw feeder of a No.1, and

the material is conveyed to a mixer barrel through a screw feeding machine;

6. Mixing: after the material completely enters the material barrel, the upper docking platform is reset, the feeding

port is automatically closed, and the mixer is in a preset time mixing;

7. Discharging: after the materials are mixed, the charging barrel of the mixer is automatically found, at this time,

the material feeding machine of the second screw of the discharging port is opened, and the discharging port is

automatically opened, and the discharge is started; and

8, The detection of the gold probe: a metal detector is arranged between the discharge port of the screw feeder

of the No.2 screw and the packaging machine, If the material contains the detection range and the metal detector

is used for alarming when the metal is used; And

9, Packaging: the mixed materials are conveyed to a packaging machine on a packaging machine through a conveyor

to start packaging.

10. Description: The material position detection system of the self-contained storage bin of the packaging machine

detects that the material on the material is full to the signal of the No.2 feeder. the feeding machine stops working,

and after the material in the packaging machine is finished, the machine is started on the screw rod of the No.2 screw,

in this case, that material in the mixer and the next working cycle is carried out after the discharge is finished;

11. Due to the double-row arrangement of the feeding buffer bin (in order to use a weighing bin), it is inconvenient to

feed on one side. The manual feeding pedal can be arranged on both sides of the buffer stock bin.