1、 Question raising

With the development of science and technology in China, research on new materials is changing rapidly. A common characteristic of new materials is that they are becoming increasingly refined, that is, the particle size of the powder is becoming smaller and smaller, even reaching the nanoscale level. When the powder is refined to a certain extent, the gravitational binding of individual particles becomes extremely small, and once there is motion disturbance, it can overcome the gravitational binding and float. Like ultra-light powder, it brings difficulties to uniform mixing.

2、 Definition of ultrafine powder

Ultrafine powder usually refers to powder with a mesh size of 1000 or 2000 or more

Or expressed as particle size: powder below 15 µ m (micrometers)

Characteristics of ultrafine powder:

1. Floatability: Because the powder is small enough to have a certain degree of motion floatability, which is similar to the floatation characteristics of ultra-light powder, it is very difficult to mix evenly;

The above picture shows the oscillation and floating phenomenon of 3000 mesh coating powder during free fall

2. The number of particles in the powder increases sharply: the smaller the particle size per unit volume, the more powder particles there are (geometric quantity increases sharply), and the more powder particles there are, the greater the mixing task. For example, within a volume of one cubic centimeter, 1000 particles with a particle size of 1mm can be placed, and 1000000 particles with a particle size of 0.1mm can be placed. It can be seen that the particle size changes by 10 times, and the powder quantity changes by 1000 times. The task of mixing one million 0.1mm particles is much larger than one thousand 1mm powder particles.

3、 Solution

In view of the above two characteristics of ultra-fine powder, micron powder and nanometer powder, floatability and rapid increase in quantity, the mixer is required to overcome these two characteristics and achieve uniform mixing.

1. Solve the floatability of ultra-fine powder, ultra-fine powder and nanometer powder

The following types of mixers are used to do the mixing experiment of ultrafine powder, micro powder and nano powder

The two types of resin micro bamboo powder participating in the experiment have particle sizes of 50 µ m (micrometer) and 30 µ m (micrometer), and the specific gravity of pigment powder is 5 µ m (micrometer). Pigment particles with a diameter less than 10 µ m belong to the category of ultrafine powder.

1) Using a 3D mixer for mixing

Mixing for one hour resulted in uneven test results. Analysis reason: The three-dimensional mixer belongs to the gravity diffusion type mixer, with a loading rate of about 50%, and there is still 50% convective diffusion space in addition to materials, which is easy to retain floating light and fine powder. During the mixing process, the phenomenon of ultrafine powder pigment floating during movement is severe, leading to mixing failure.

2) Mixing using a horizontal spiral belt mixer

Mix for one hour, but the mixing result is uneven. Analysis reason: The horizontal spiral belt mixer belongs to the type of forced shear mixer with moving blades. During the mixing process, when ultra-fine powder and micro powder are stirred by the moving blades, the particle size is too small and too light, which easily floats above the material in the bucket, making it difficult to achieve uniform mixing.

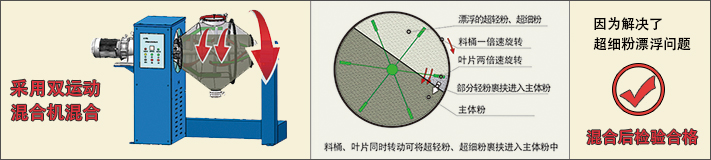

3) Adopting dual motion ® Mixer mixing

Mix for one hour and the mixing result is qualified. Analysis of reasons: Firstly, dual motion ® The rotation of the mixing machine barrel and forced mixing of the blades belong to medium and low speed operation, which is not easy to cause light powder to float; The second is dual movement ® The loading rate of the mixer is as high as 80%, leaving limited space for micro powder and ultrafine powder to float; The third is dual movement ® The rotation of the mixing machine bucket and the rotation of the blades can simultaneously transport floating micro powder and ultrafine powder into the main powder.

2. Solve the problem that the number of ultra-fine powder, micro powder and nano powder increases sharply and the mixing task increases

The problems of ultrafine powder, increased quantity, and increased mixing tasks can be solved from two aspects:

1) Extend mixing time

Extending the mixing time is used to solve the problem of increasing the mixing task, but the mixing time cannot be unlimited. Long term mixing can cause adverse factors such as powder heating and changes in powder characteristics.

2) Choose a mixer with strong mixing ability

Currently, among the existing mixers in the market, there are significant differences in their mixing capabilities due to their different mixing principles and different designs of their motion structures. Comprehensive comparison of dual sports ® The mixing ability of the mixer is relatively strong, as its drum rotates for gravity diffusion type mixing and the blades rotate for forced shear stirring type mixing, greatly enhancing its mixing efficiency and mixing ability. Therefore, choose a dual sport with strong abilities ® The mixer can better solve the problem that the quantity of micro powder, nano powder and ultra-fine powder increases sharply and the mixing task is heavy.