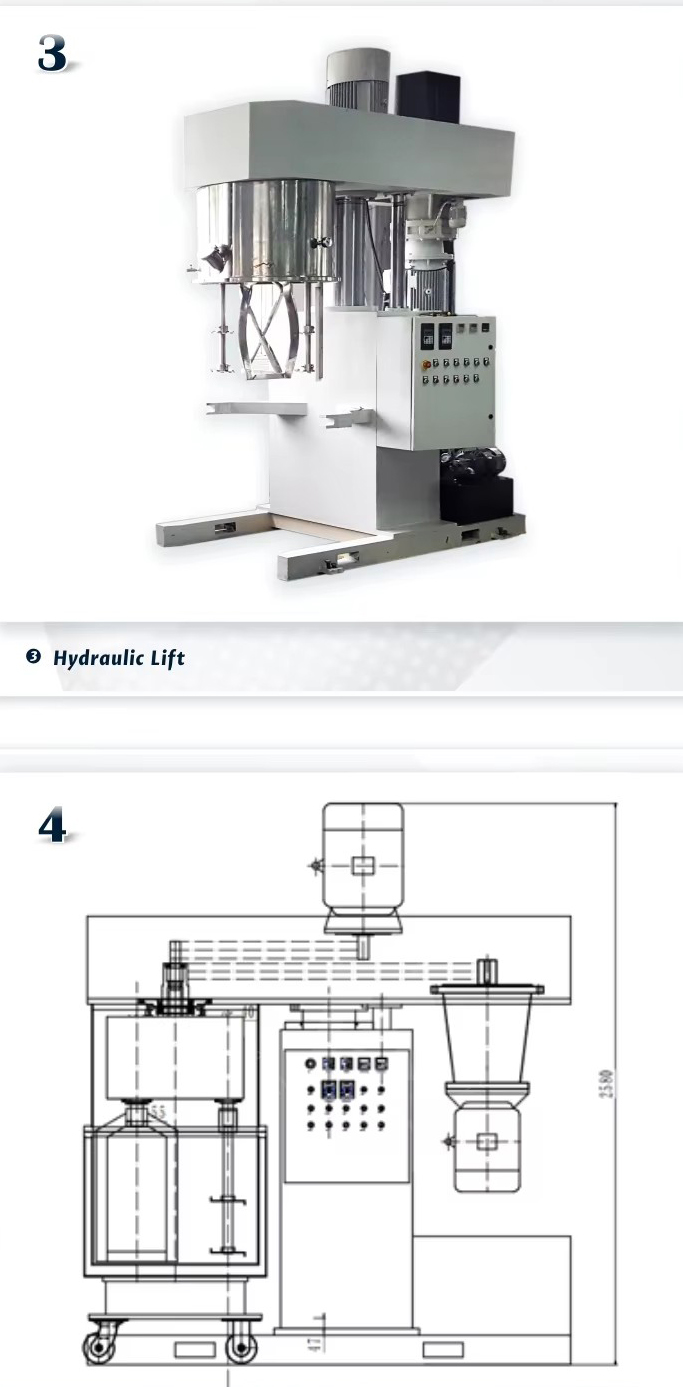

Powerful Double Planetary Mixer is a new mixing machine with high performance, high efficiency, easy to clean and to maintain, which is innovated and improved based on double planetary mixer. The Double agitators of this equipment rotate and at the same time revolve around the axle, the agitators are divided by the viscosity and characteristics of the material, usually include paddle type, twist type, claw type, frame type etc., have good mixing, reacting, kneading, dissolving effect. The high-speed disperser consists of multi-layer toothed disc with super high linear speed, it also rotates and at the same time revolve around

the axle, with strong dispersing effect so that can disperse the powder (additive) in the liquid rapidly. The mixer is equipped with a separate set of scraper to scrape the sides of the barrel and the mixing paddle can be added a scraper as well, so that it can scrape the bottom of the barrel and avoid dead corner to ensure the stability of the product. Double Planetary Mixer adopts planetary gear wheel drive, there is a large output torque, suitable for high temperature, high solids, high viscosity, and other difficult working conditions; this equipment is closed design, can be used with a vacuum system to realize vacuum mixing, mixing bucket can be designed with a heating jacket, matching mold temperature controller, to realize thermostatic mixing function, it’s the first choice of mixing equipment for the high-viscosity materials.