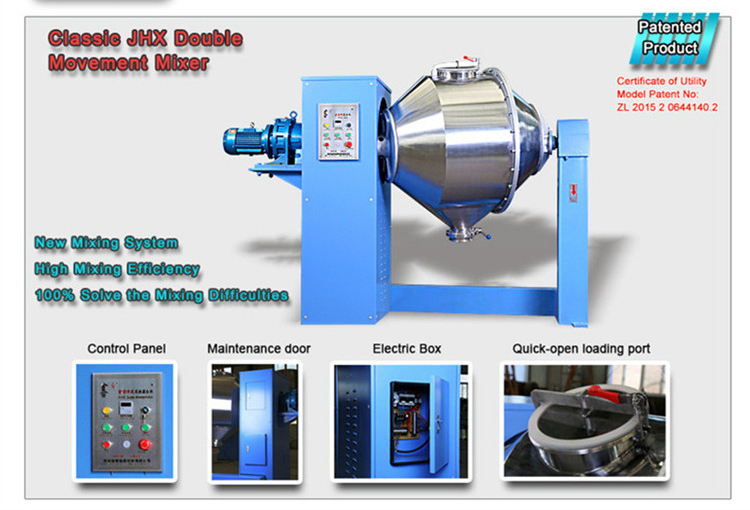

In the food additives and veterinary drug pharmaceutical and other industries, there is a large mixing batch, and at the same time the mixing uniformity is relatively high, and it is more difficult to make the mixer specification larger, and the double movement ® mixer mainframe developed by us solves this problem well. So far, we have provided customers with a number of 7000L of double movement ® mixer mainframes, and achieved good mixing results in the process of customer use, mixing batch and large results.

With the large scale mixing machine equipment, its mixing efficiency will be appropriately reduced, in order to solve this problem, we increase the distribution density of moving blades inside the machine and other technologies to make up for the shortcomings of the mixing efficiency reduction caused by the large-scale equipment.

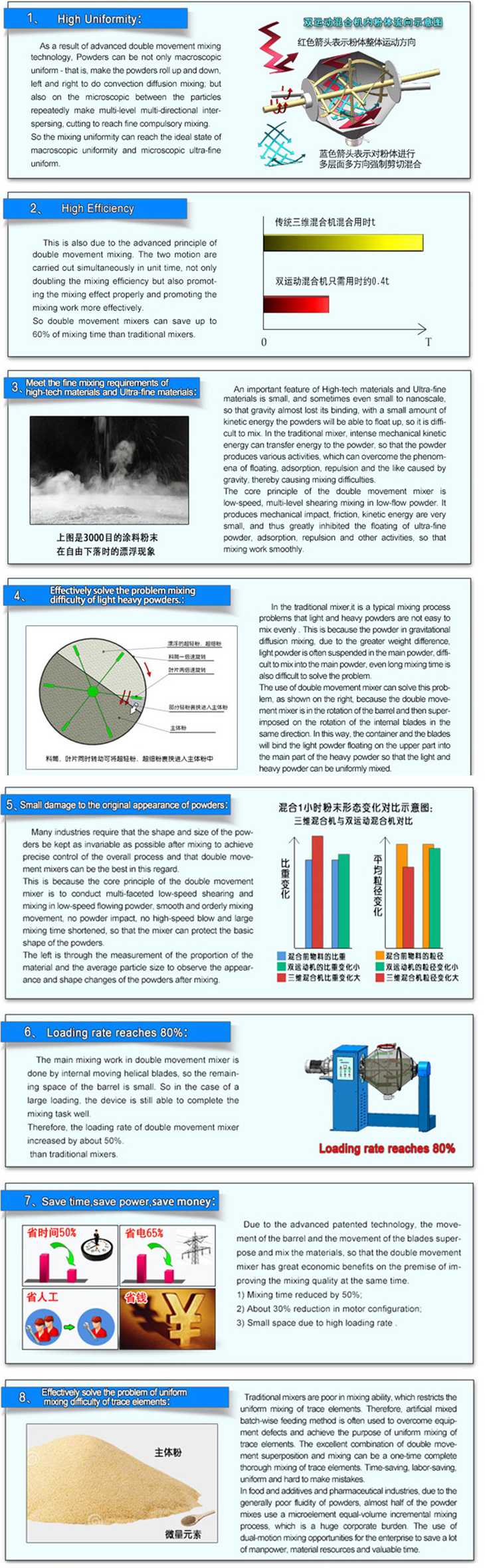

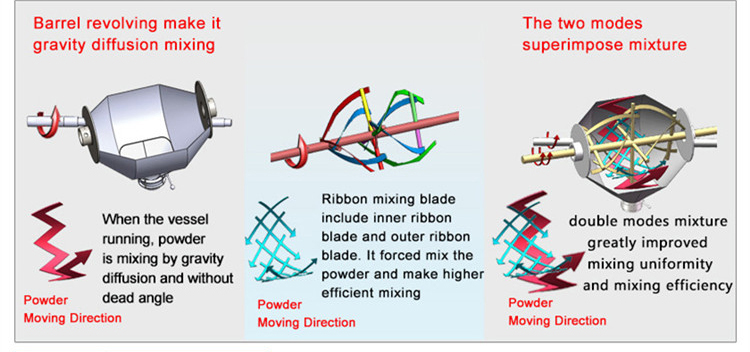

Using advanced double movement superposition mixing technology, it realizes two functions of gravity diffusion mixing and forced shear mixing on one device. It can achieve macroscopic uniformity - that is, let the powder roll up and down, left and right convection diffusion and uniform mixing; It can also repeatedly intersperse and cut between particles and particles at the microscopic level of the powder to achieve fine forced mixing. Therefore, the mixing uniformity can reach the ideal state of macroscopic uniformity and microscopic ultra-fine uniformity.

This is also because of the advanced principle of superimposed mixing of two movements, two movements are carried out at the same time in a unit time, which not only doubles the mixing efficiency, but also promotes each other just right, and promotes the mixing work more effectively. As a result, the double movement ® mixer saves up to 60% of time compared to conventional mixers.

In the double movement ® mixer, the main mixing work is done by the internal moving spiral blades, so the remaining space of the barrel can be small. Therefore, in the case of a large loading rate, the equipment can still perform the mixing task well. As a result, the double movement® mixer has a loading capacity of more than 50% compared to traditional mixers.

| Model | Barrel Capacity(L) | Max. Loading (L) | Barrel speed(r/min) | Blade speed(r/min) | Motor Power(kw) | Machine Dimension | Weight(kg) |

| (L*W*H mm) | |||||||

| JHX1000 | 1000 | 800 | 11 | 22 | 7.5 | 2550x1350x1900 | 2300 |

| JHX1500 | 1500 | 1200 | 8 | 16 | 15 | 2850x1870x2240 | 2600 |

| JHX2000 | 2000 | 1600 | 6 | 12 | 18.5 | 3200x1970x2470 | 2900 |

| JHX3000 | 3000 | 2400 | 6 | 12 | 22 | 3800x2100x2900 | 3500 |

| JHX5000 | 5000 | 4000 | 5.5 | 11 | 30 | 4500x2500x3200 | 4500 |

| JHX7000 | 7000 | 5600 | 5 | 10 | 37 | 4750x2650x3800 | 6000 |

| The specifications between JHX7000~JHX10000 are customized according to the needs of customers. | |||||||