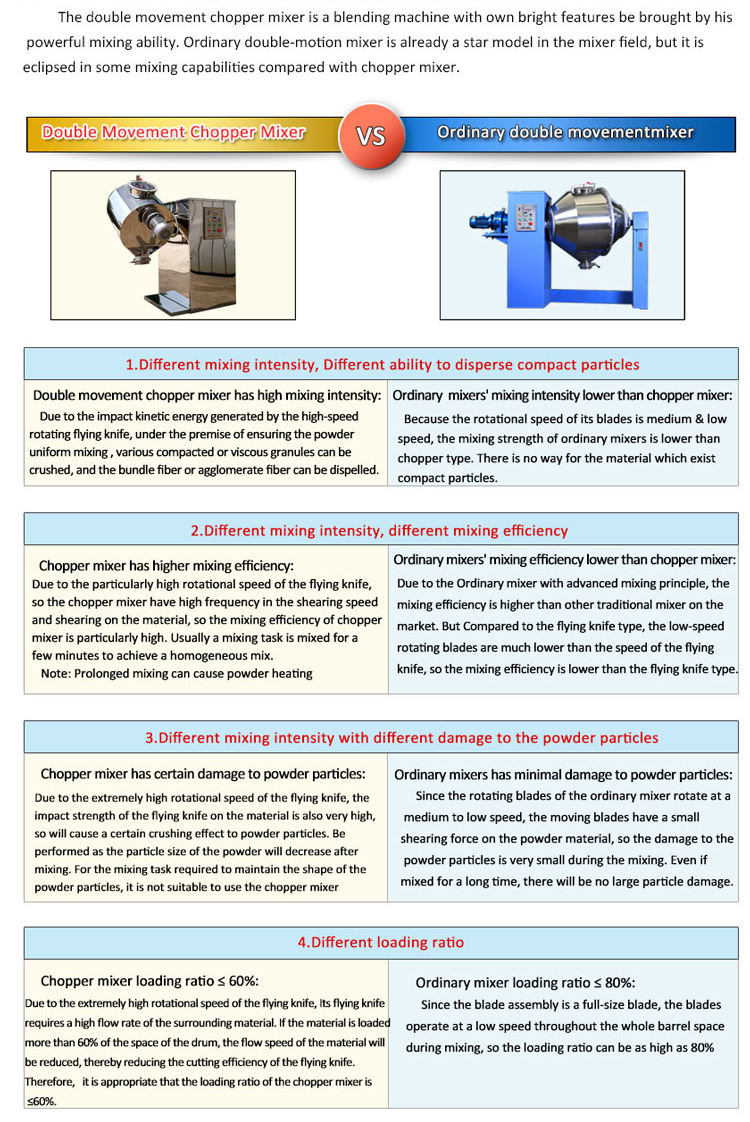

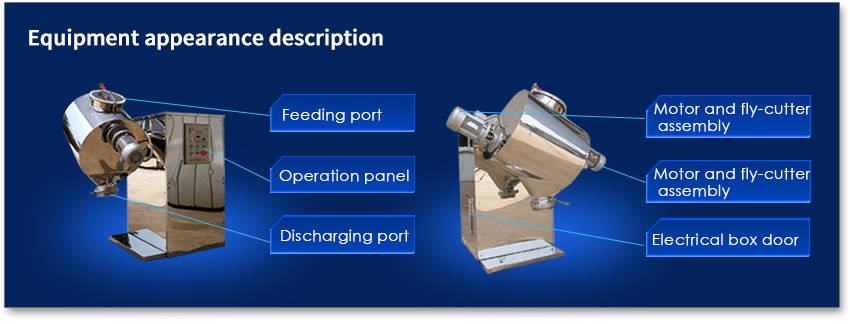

The blades of the dual motion® mixer rotate at medium and low speeds, the purpose of which is to keep the powder particle's shape unchanged as much as possible, if there are hard particles or viscous particles with strong adhesion in the powder, such medium and low speed rotating blades can not effectively break it.

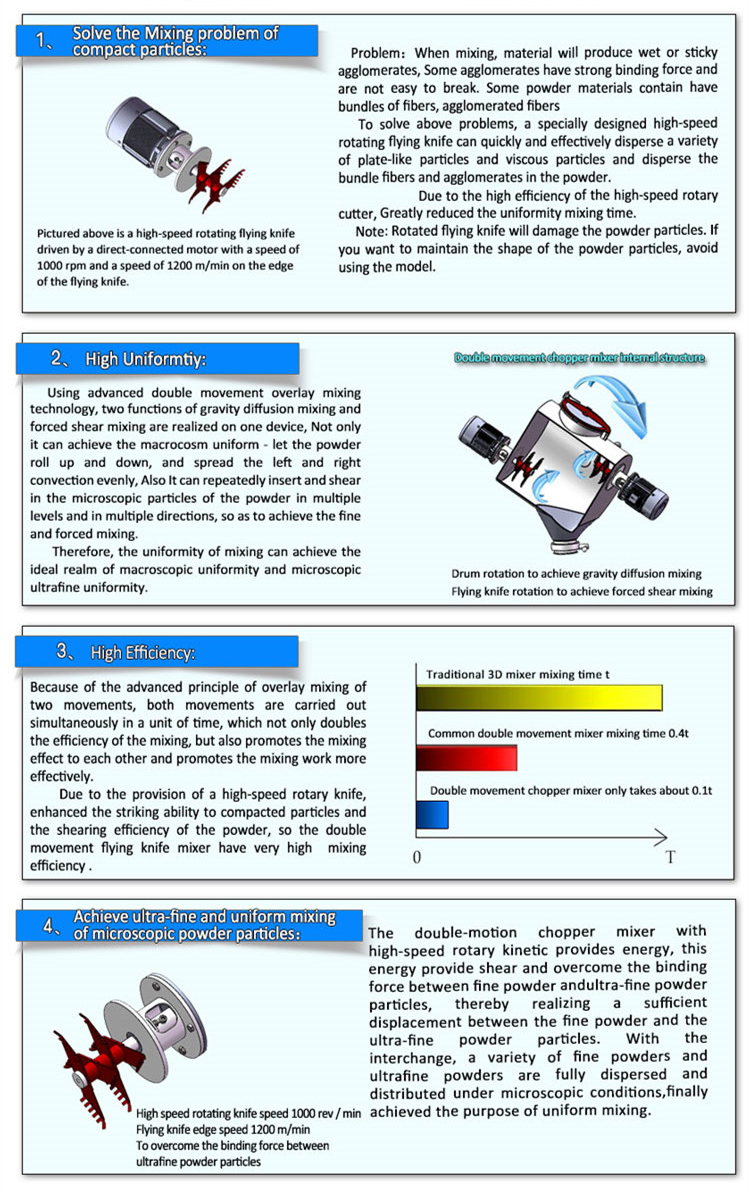

The dual motion® flying knife mixer is to set up a high speed rotating flying knife on the moving barrel, which is to use a high speed flying knife to cut and hit the powder on the basis of gravity diffusion mixing of the powder, which is particularly effective in breaking the hard particles and viscous particles in the powder. At the same time, it can also solve the problem of uniform mixing between fiber and powder.

This is the innovative contribution of our team for 18 years, enriching the diversity of the double movement mixer camp and providing the mixer industry with a super capable double motion ® mixer.

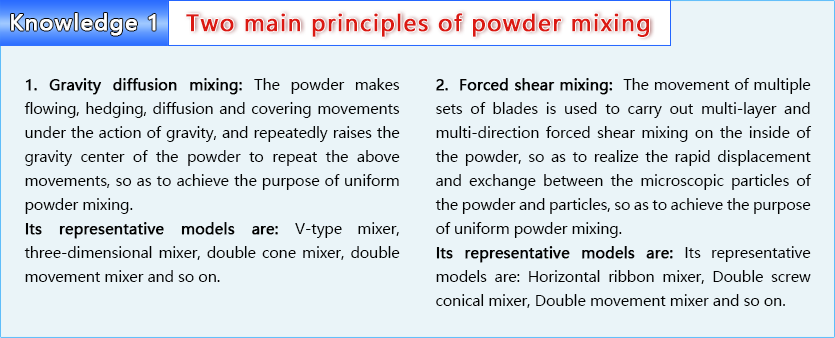

Using advanced dual movement overlay mixing technology, it realizes two functions of gravity diffusion mixing and forced shear mixing on one mixer. It can achieve macroscopic uniformity: it means let the powder roll up and down, left and right convection diffusion and uniform mixing; It can also repeatedly intersperse and cut between particles and particles at the microscopic level of the powder to achieve fine forced mixing. Therefore, the mixing uniformity can reach the ideal state of macroscopic uniformity and microscopic ultra fine uniformity.

Because of the advanced principle of superimposed mixing of two movements, two movements are carried out at the same time in a unit time, which not only doubles the mixing efficiency, but also promotes the mixing effect of each other just right, and promotes the mixing work to be carried out more effectively. Due to the setting of high-speed rotating flying knives, the striking ability of the hardened particles and the shearing efficiency of the powder are improved, so the mixing efficiency of the double motion® flying knife mixer is very high.

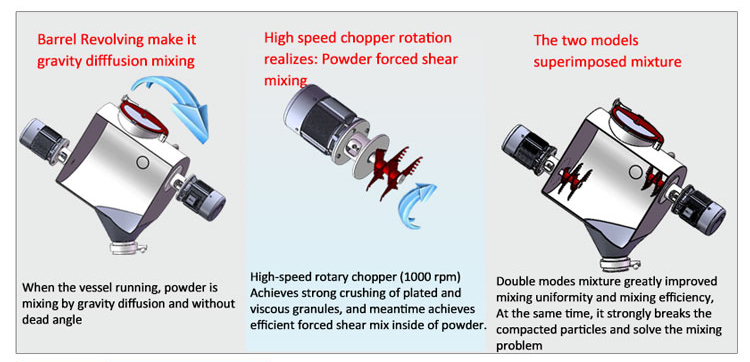

| Model | Vessel(L) | loading(L) | Running speed (r/min) | Chopper speed(r/min) | motor(kw) | chopper knife(kw) | size(mm) |

| JHF20 | 20 | 12 | 25 | 950 | 0.75 | 0.37 | 960*435*987 |

| JHF50 | 50 | 30 | 25 | 950 | 1.1 | 0.55 | 1190*550*1232 |

| JHF100 | 100 | 60 | 21 | 950 | 1.1 | 0.55 | 1267*672*1407 |

| JHF200 | 200 | 120 | 16 | 950 | 1.5 | 0.75 | 1453*780*1590 |

| JHF400 | 400 | 250 | 15 | 950 | 2.2 | 1.1 | 1848*812*1772 |