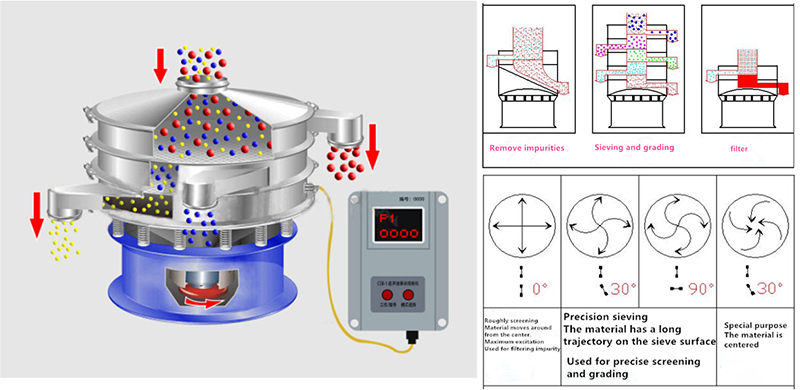

Ultrasonic powder vibrating screen is used for material classification or impurity removal. By adding ultrasonic waves (mechanical waves) to the screen, the ultrafine powder is subjected to tremendous ultrasonic acceleration, suppressing blockage factors such as adhesion, friction, and wedging, and improving screening and cleaning efficiency.

| Model | Effectiv e diameter (mm) | Effective sieving area (m2) | Screen mesh | Layer | Powder(KW) | |

| Vibration | Common | |||||

| JHVS-400 | Φ340 | 0.0907 | 2-500 | 1-5 layers | 0.18 | -- |

| JHVS-600 | Φ540 | 0.2289 | 0.25 | 0.75 | ||

| JHVS-800 | Φ730 | 0.4183 | 0.55 | 1.1 | ||

| JHVS-1000 | Φ900 | 0.6359 | 1.1 | 1.5 | ||

| JHVS-1200 | Φ1100 | 0.949 | 1.1 | 1.5 | ||

| JHVS-1500 | Φ1400 | 1.5386 | 1.5 | 2.2 | ||

| JHVS-1800 | Φ1700 | 2.2687 | 4 | 3 | ||

| JHVS-2000 | Φ1886 | 2.7922 | 4 | 3 | ||