QM Roll ball mill, a type of grinder machine, is a cylindrical device used in grinding (or mixing) materials like ores,chemicals, ceramic raw materials and paints, etc. It is widely applied to industries of electronic material, mineral material, ceramics, magnetic material, building material, biological medicine, cement, metal powder, nonmetallic minerals, etc. The machine consisits of mechanical transmission mechanism, PLC control and grinding jar three main parts, with characteristics of beautiful design,compact structure, easy operation, high efficiency, and uniform granularity, etc.

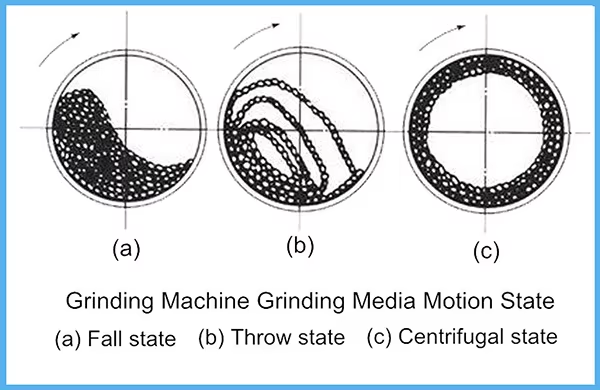

When roll ball mill work, the cylinder body of grinding medium and material together along with cylinder rotate ascending to a certain height, from the cylinder wall along the parabola whereabouts by gravity, the grinding media and the material in the grinding tank high speed rolling, generating a strong shear, impact, roll to reach the purpose of crushing, grinding, dispersion, emulsification materials.

| Applied Industry | Mill Substance |

| Laboratory | Soil, metal, rigid specimens, powder material, etc |

| Medical | Medicine, drug, pharmaceutical, pills, etc |

| Mineral | Ore, stone, mine, litharge, alumina, coal, chromium, chrome, etc |

| Construction | Stone, glass, cement, concrete, sand, slag, etc |

| Ceramic | Pottery, porcelain, clay, chinaware, ceramic glaze, etc |

| Paint | Ink, color, coating, pigment, spices, etc |

| Food | Grain, sugar, pepper, slice, chocolate, malt, plant material, etc |

| Geology | Powder metallurgy, corrosion materials, catalysts, chemical, etc |

| Others | Comestic, herb, clinker, pearl, linestone, environmental, etc |

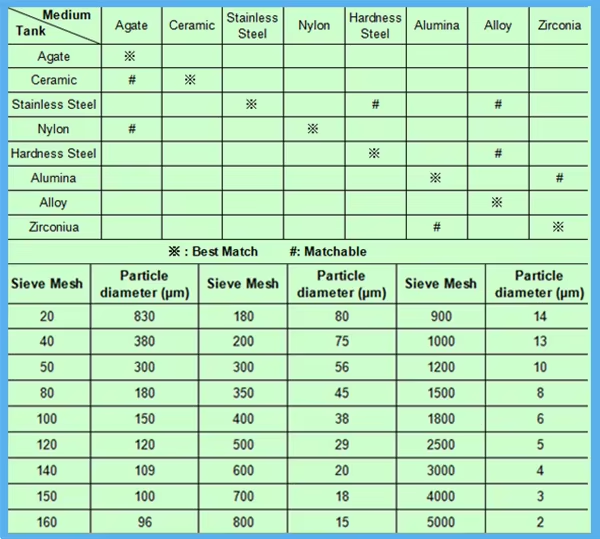

Every QM Ball Mill Machine is equipped with a round frame sieve. While grinded powder passing through the sieve, the particle can be classified into different sizes. The screen has 10 types, including 20/40/60/80/100/120/140/160/180/200 sieve number. You can get different size powder by choosing the appropriate screen. Matches between sieve & particle is as followed:

| QM Series Horizontal Ball Mill Machine | |||||||

| No. | Model | Barrel volume(L) | Working capacity(L) | Barrel speed | Motor Power (kw) | Dimension | Weight |

| (r/min) | L×W×H(mm) | (kg) | |||||

| 1 | QM150 | 150 | 75 | 37 | 3 | 1527×960×1181 | 400KG |

| 2 | QM250 | 250 | 125 | 29 | 5.5 | 2290×960×1110 | 650KG |

1.Smooth operation, high-efficiency, energy-saving, low noise, no pollution.

2.With automatic unloading machine, material and ball separate automatically , convenient discharge.

3.For dry and wet grinding, can deal with all kinds of hard material, rough and fine grinding or mixture materials.

4.Ball mill crushing in sealed cylinder, no dust flying, high material purity, and carried under inert air flow, thus used in some inflammable and explosive materials broken.

5.Hollow shaft adopts cast steel, lined with removable, rotary wheel adopts gear hobbing machining, cylinder body with wear-resisting liner, good abrasion resistance, high grinding efficiency.

6.Can choose stainless steel, carbon steel, manganese steel, alumina, zirconia, polyurethane, nylon, etc as liner according to customer's requirement.