Planetery ball mill machine General Introduction:

(Oil seal mute)Planetary ball mill is a necessary device for mixing,fine grinding,small samples prepared,dispersion of nanometer, R&D of new product and small batch production for high tech materials.

The equipment with small volume,comprehensive function,high efficiency,low noise which is the ideal device of obtaining micro-particle research samples used for research and development institute,collages and universities,entire laboratory.

The samples could be ground under vacuum state with using the vacuum ball mill jars.

It is widely used in geology,mineral,metallurgy,electronic,building material,ceramic,

chemical,light industry,medicine,beauty,environment production,tea and so on.

According to the processing requirement to set the rotation speed and alternate time of forward and reversal rotation and set the total grinding time.

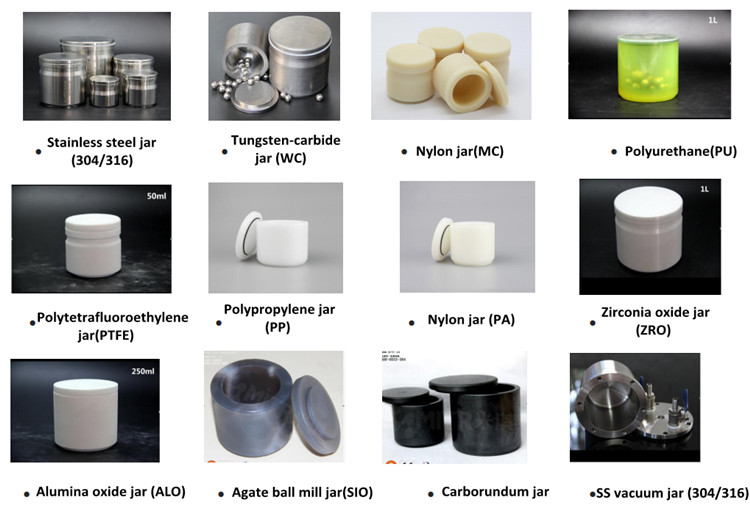

Mill jars and balls:

Our factory can provide 304 stainless steel jar, Tungsten carbide jar(YG8),

ceramic jar / corundum jar/ alumina jar, zirconia jar, agate jar. nylon jar, PU jar,

PTFE jar. We can also provide the ball material of stainless steel, ceramic,

corundum, alumina, zirconia, agate, tungsten carbide.

1.Material of ball mill jar:

2) Special ball mill jar for vacuum/inert gases protection:

3) Material of grinding ball:

3) Material of grinding ball:

Examples of milling tasks:

Examples of milling tasks:

Details:

Installed picture of each material ball mill jar :

Installed picture of each material ball mill jar :

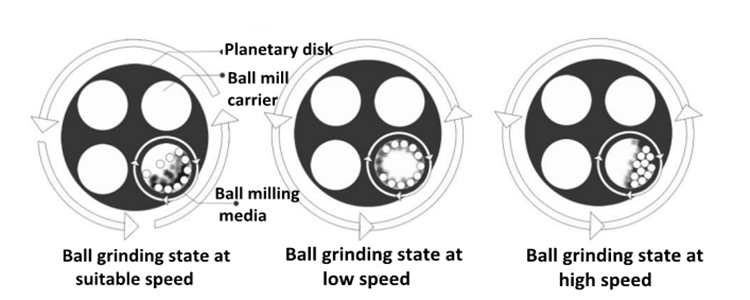

Oil seal mute planetary Ball Mill has four ball grinding tanks installed on one turntable.When the turntable rotates,

the tank axis makes planetary movements,The balls and samples inside the jars are impacted strongly in high

speed movement, and samples are eventually ground into powder. The ball mill can use for dry and wet

grinding and also can mix products of different granularity and materials.

Working mode: Two or four ball milling jars working at the same time and the maximum sample loading amount:

Volume of ball milling jar 2/3, feeding granularity:soil material ≤ 10mm other material ≤ 3mm discharge granularity:

the minimum can up to 0.1um (i.e. 1.0 *10mm-4)

| Model | Power | Voltage KW | frequency conversion power KW | Ball mil l Jar | Vacuum Jar | Rotation Speed r/min | Noise ≤db(A) | |

| Revolution (adjustable) | Rotation (adjustable) | |||||||

| JHMB0.4L | 220V 50HZ | 0.55 | 0.4 | 100ml | no | 30-450 | 60-900 | ≤60db |

| JHMB-1L | 220V 50HZ | 0.75 | 0.55 | 250ml | 100ml | 30-450 | 60-900 | ≤60db |

| JHMB-2L | 220V 50HZ | 1.1 | 0.75 | 500ml | 250ml | 30-400 | 60-800 | ≤60db |

| JHMB-4L | 220V 50HZ | 1.1 | 0.75 | 1L | 500ml | 30-400 | 60-800 | ≤60db |

| JHMB-8L | 220V 50HZ | 1.5 | 1.5 | 2L | 2L | 30-280 | 60-560 | ≤60db |

| JHMB-12L | 380V 50HZ | 1.5 | 2.2 | 3L | 3L | 30-260 | 60-520 | ≤60db |

| JHMB-16L | 380V 51HZ | 3 | 4 | 4L | 4L | 30-230 | 60-460 | ≤60db |

| JHMB-20L | 380V 52HZ | 3 | 4 | 5L | 5L | 30-230 | 60-460 | ≤60db |

| JHMB-40L | 380V 53HZ | 3 | 4 | 10L | 10L | 30-180 | 60-360 | ≤90db |

| JHMB-60L | 380V 54HZ | 4 | 5.5 | 15L | 15L | 30-170 | 60-340 | ≤90db |

| JHMB-80L | 380V 55HZ | 7.5 | 7.5 | 20L | 20L | 30-160 | 60-320 | ≤90db |