Different from traditional batch type mixer, continuous mixer provide a more economical alternation for big capacity to meet process requirement. The weighing, loading, mixing and discharge steps finish simultaneously and continuously in a continuous mixing process. For many applications, continuous mixing offers a cost effective alternative to traditional batch mixing with lower processing costs and fewer labor requirements. The continuous mixer can handle up to 5 different materials at one time, mixing powders with another powder, powder with a liquid or several liquids together to create a homogeneous product free of any agglomerates or lumps.

Different from traditional batch type mixer, continuous mixer provide a more economical alternation for big capacity to meet process requirement. The weighing, loading, mixing and discharge steps finish simultaneously and continuously in a continuous mixing process. For many applications, continuous mixing offers a cost effective alternative to traditional batch mixing with lower processing costs and fewer labor requirements. The continuous mixer can handle up to 5 different materials at one time, mixing powders with another powder, powder with a liquid or several liquids together to create a homogeneous product free of any agglomerates or lumps.

A. High speed

Continuous mixers are generally driven by gear reducers, and the motor uses a variable frequency motor to adjust the speed. The spindle speed is several times higher than that of intermittent mixers to ensure the mixing effect.

B. Mixer form one

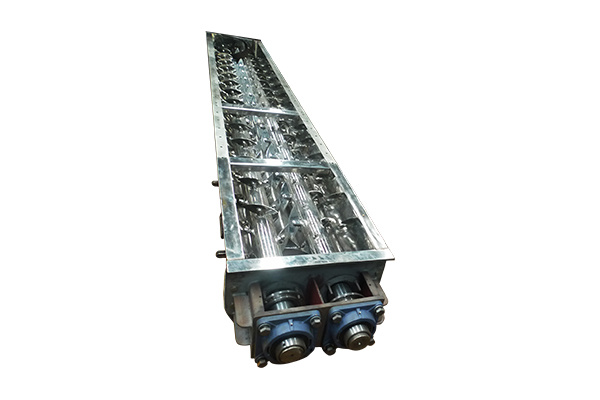

Because of the different characteristics of the materials, different agitator types are used, such as paddle type and ribbon type as shown in the picture.

C. Mixer form two

Because of the different characteristics of the materials, different agitator types are used, such as the plow type and the double-shaft paddle type as shown in the picture.

D. Atomizing nozzle

An atomizing nozzle can be added above the flying knife to achieve liquid addition and mixing. Since the material at this position has a smaller density under shearing by the flying knife, the atomized liquid material is more likely to enter and mix with the powder.

E. Optional flying knife

For some special materials, a flying knife can be optionally used to deaggregate and break up the materials.

F. Feeding method

The feed generally uses a screw conveyor or a belt conveyor, and a frequency converter is used to adjust the feed speed to match the discharge speed of the mixer.