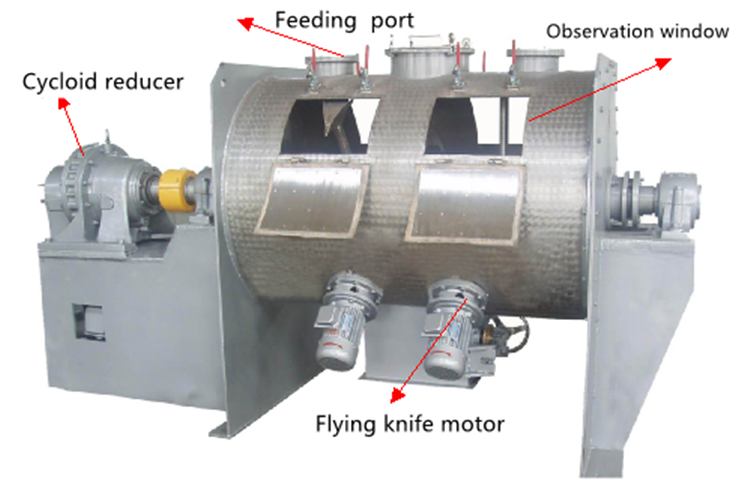

JHG Horizontal Continuous plough mixer

The Horizontal plough mixer include transmission mechanism, horizontal cylinder, coulter and flying cutter. Under the coulter’s role, the material makes convection movement along with the cylinder and cast by flying cutter with high speed rotation when passing by it, achieving uniform mixing in the shorter time. It can apply to much mix of solid and liquid and some compound process such as creating wet powder and drying, especially to the mix of viscosity or colloid additive. As a ruesult, this JHG plough mixer is yours best choice because it could mix the Viscous powder very well !

Technical Parameters:

| MODEL | Capacity(M³) | Loading Rate | Motor Power(KW) | Size(MM) | weight(KG) |

| JHG-100 | 0.1 | 0.4-0.6 | 3 | 1270×865×850 | 430 |

| JHG-300 | 0.3 | 0.4-0.6 | 4 | 2070×1050×1150 | 950 |

| JHG-500 | 0.5 | 0.4-0.6 | 5.5 | 2180×1200×1300 | 1100 |

| JHG1000 | 1 | 0.4-0.6 | 11 | 2830×1620×1550 | 1800 |

| JHG2000 | 2 | 0.4-0.6 | 18.5 | 3420×1810×1758 | 2520 |

| JHG3000 | 3 | 0.4-0.6 | 18.5 | 3420×2045×1983 | 3200 |

| JHG4000 | 4 | 0.4-0.6 | 22 | 4200×2140×2123 | 4836 |

| JHG6000 | 6 | 0.4-0.6 | 30 | 4680×2290×2448 | 8775 |

| JHG8000 | 8 | 0.4-0.6 | 45 | 5560×2390×2608 | 9360 |

| JHG10000 | 10 | 0.4-0.6 | 55 | 5140×2390×2850 | 9750 |

| JHG12000 | 12 | 0.4-0.6 | 55 | 5720×3110×2960 | 10660 |

| JHG15000 | 15 | 0.4-0.6 | 75 | 5920×3280×3140 | 11050 |