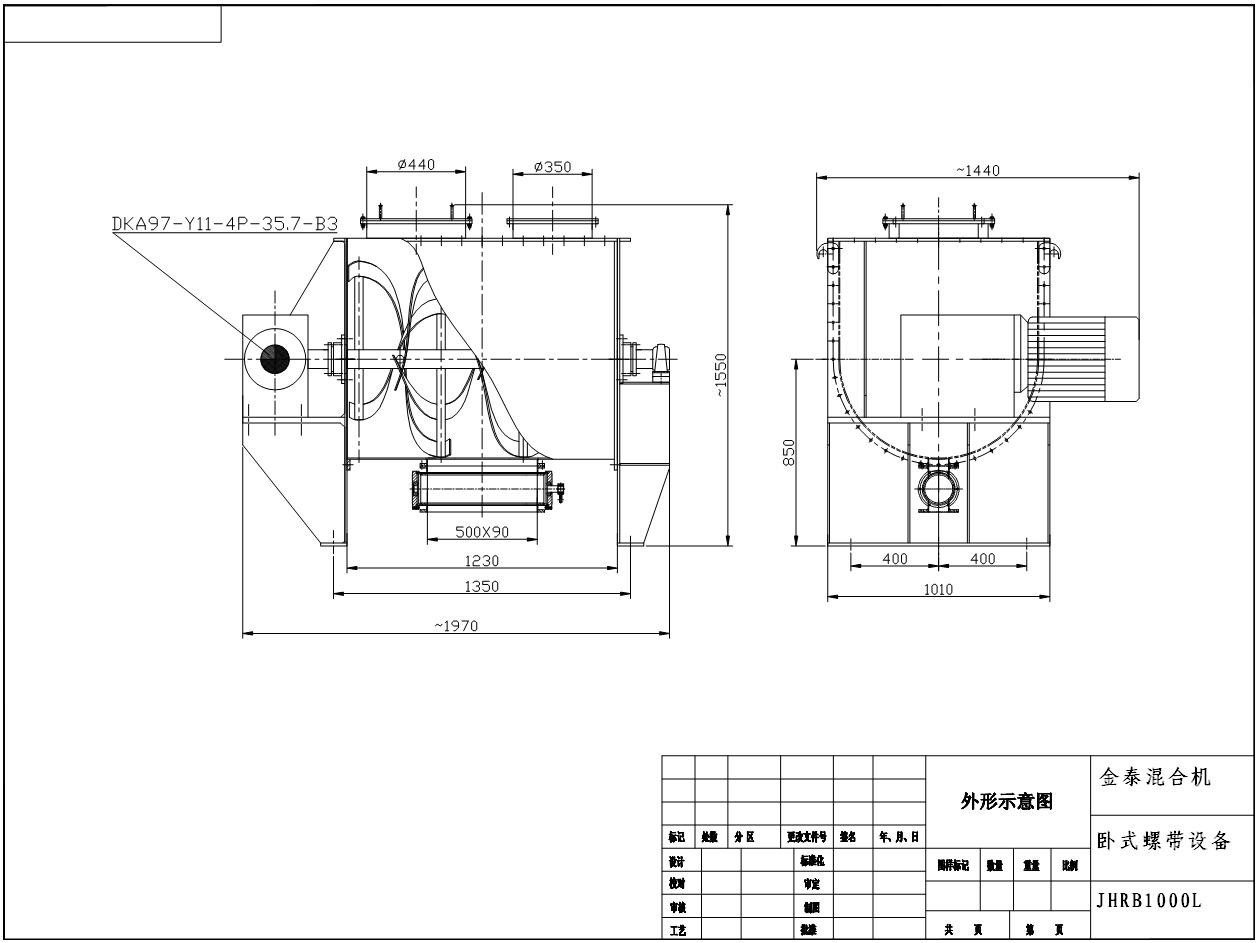

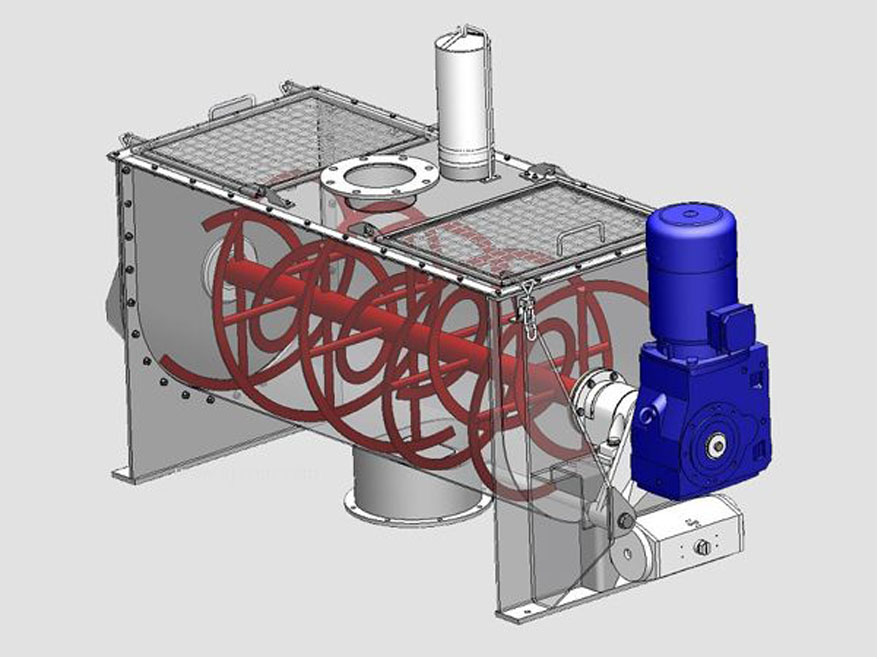

The JHRB horizontal Ribbon mixer consists of a U-shaped container, transmission components, and ribbon with mixing blades. The mixing ribbon blades usually have two or three layers, with the outer spiral collecting the material from the side to the center, and the inner spiral conveying the material from the center to the side, forming convective mixing. The horizontal ribbon blender is a good mixing equipment that mixes viscous or cohesive powder and adds liquid and saccharified substances to the powder. The mixer lid can be fully opened for cleaning and equipment replacement.

The horizontal ribbon blender consists of a U-shaped horizontal groove and a special ribbon mixer. The ribbon stirrer consists of a set of inner and outer ribbon blades. The external ribbon moves the material to the center of the groove, while the inner ribbon moves the material to the outside of the groove. The ribbon also rotates at a speed of approximately 50 RPM/mins, thereby moving the material radially and laterally to ensure complete mixing in a short period of time. The Ribbon blender loading ratio is 30% to 60%.

| Model Project | Total Volume (M³) | Loads coefficient | Electrical | Size(mm)× Max-diameter ×High | Equipment weight (kg) |

| machiney | |||||

| power (KW) | |||||

| JHRB-150 | 0.15 | 0.4-0.8 | 3 | 1190×740×770 | 330 |

| JHRB-300 | 0.3 | 0.4-0.8 | 5.5 | 2030×630×980 | 720 |

| JHRB-500 | 0.5 | 0.4-0.8 | 7.5 | 2320×730×1130 | 980 |

| JHRB1000 | 1 | 0.4-0.8 | 11 | 2800×920×1320 | 1700 |

| JHRB1500 | 1.5 | 0.4-0.8 | 15 | 3180×1020×1550 | 1800 |

| JHRB2000 | 2 | 0.4-0.8 | 15 | 3310×1120×1640 | 2100 |

| JHRB3000 | 3 | 0.4-0.8 | 18.5 | 3750×1290×1820 | 3000 |

| JHRB4000 | 4 | 0.4-0.8 | 22 | 4220×1400×1990 | 3980 |

| JHRB5000 | 5 | 0.4-0.8 | 30 | 4220×1500×2100 | 4620 |

| JHRB6000 | 6 | 0.4-0.8 | 37 | 4700×1610×2260 | 6180 |

| JHRB8000 | 8 | 0.4-0.8 | 45 | 4420×2150×2470 | 8200 |

| JHRB10000 | 10 | 0.4-0.8 | 45 | 5520×2960×2720 | 8920 |

| JHRB12000 | 12 | 0.4-0.8 | 45 | 5720×3010×2840 | 9520 |

| JHRB15000 | 15 | 0.4-0.8 | 55 | 5840×3540×2940 | 9950 |