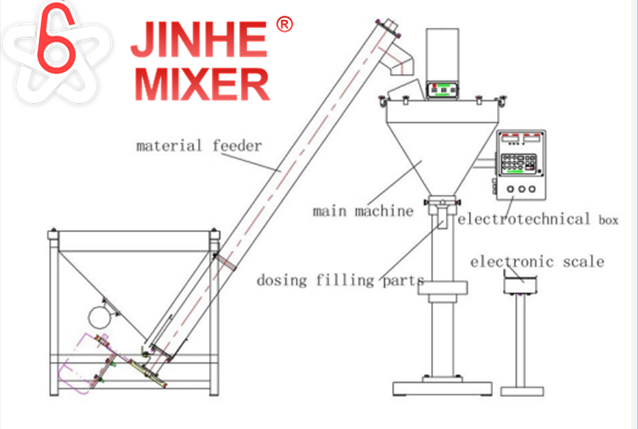

Description:

This type can do measuring and filling work. Due to the special design, so it fits more

to the fluidic or low-fluidity materials, like milk powder, gourmet powder ,solid drink,

white sugar, dextrose, coffee, fodder , solid medicine, agriculture pesticide, granularity

additive, dyestuff, and so on. LCD or touch screen control( in Chinese or English),

Servo-motor driving screw. The surface of whole machine is made by stainless steel

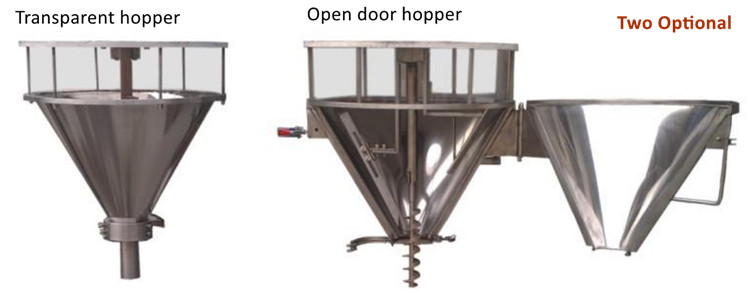

material except of motor. Knockdown Transparent hopper, which could be washed

without tooling.

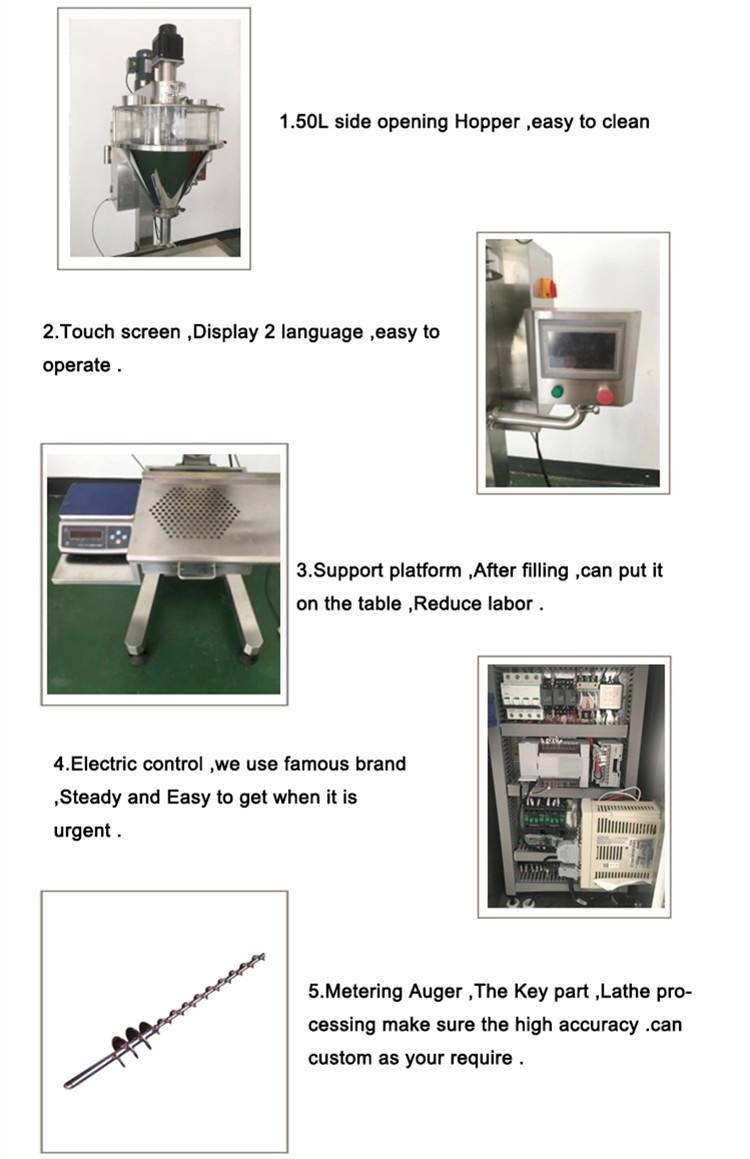

Features:

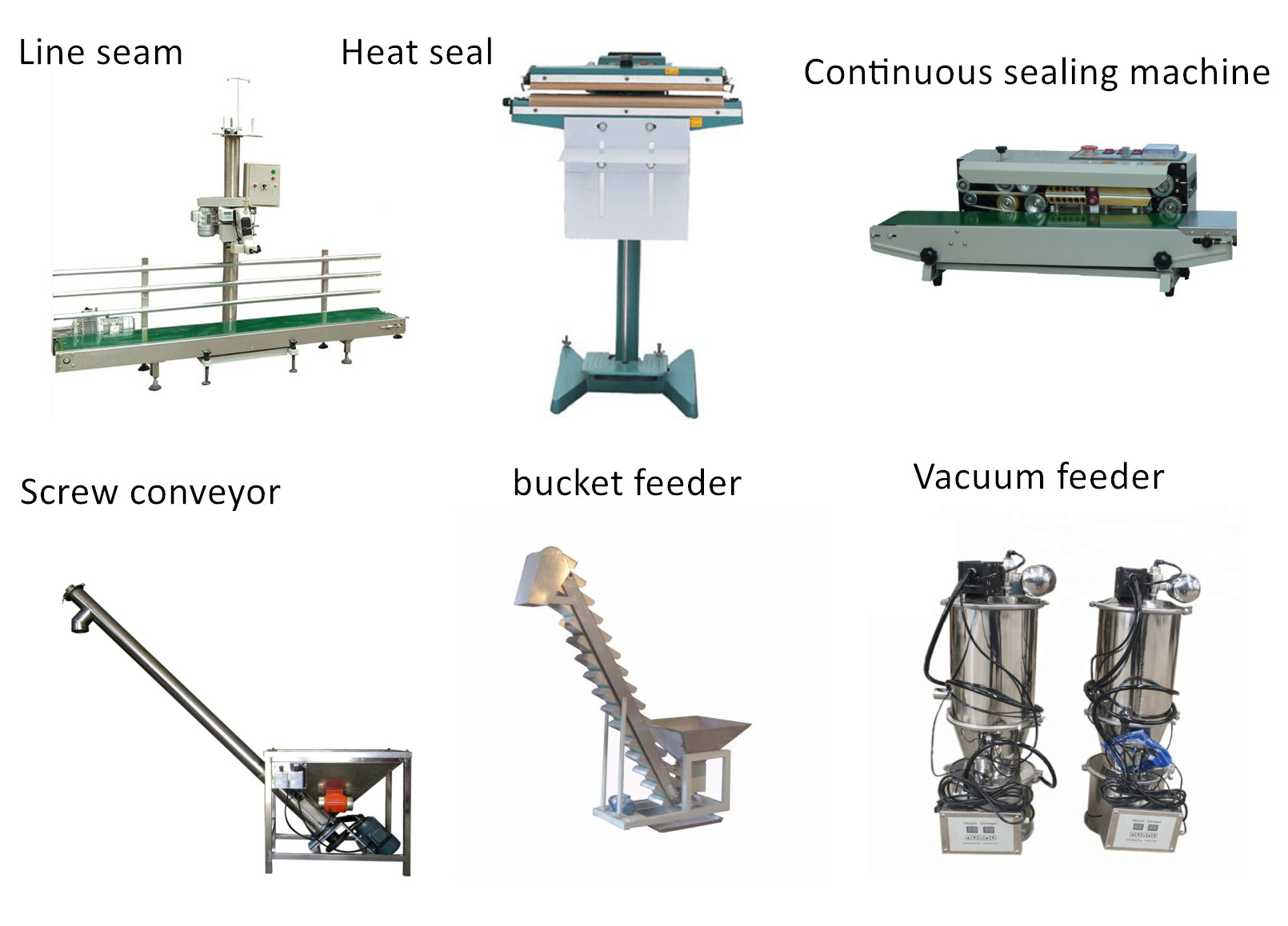

1.Dexterous and flexible, easy removal. There is no limit of packaged container. It is

widely used invariable materials and package-weight specifications.

2.High speed response(exclusive in china)on-off or servo motor drive screw.High

precision,high speed, big torsional moment, long life to use.

3.LCD or LED,simply visual supervisory.Stepless adjust the net weight.Change the

working parameter at any time,easy to control.Change the working parameter at

any time, easy to control.

4.Save the parameter of each product to later use.10 sets of magistral fomula save

at the most.

5.Fit for lots of material range from fine-powder to coarse-granule,if change the

screw attachment.Dust- collector set on dust material situation to absorb dust

spout out.

| Metering Model | Auger rotation filling traced by weighing feedback |

| Packaging Weight | 10 - 5000g(The screw attachment is to be changed) |

| Packaging Accuracy | ±3‰ |

| Motor | AC Servo motor |

| Control | Touch screen & PLC control |

| Free scale precision | 1g |

| Filling Rate | 40 - 120 times/min |

| Power Supply | 3P /220-415V 50/60Hz |

| Total Power | 1.4KW(enlarged type is 1.9KW) |

| Total Weight | 280kg |

| Overall Dimensions | 1140*710*2200mm |

| Hopper Volume | 50L(Enlarged size 70L) |