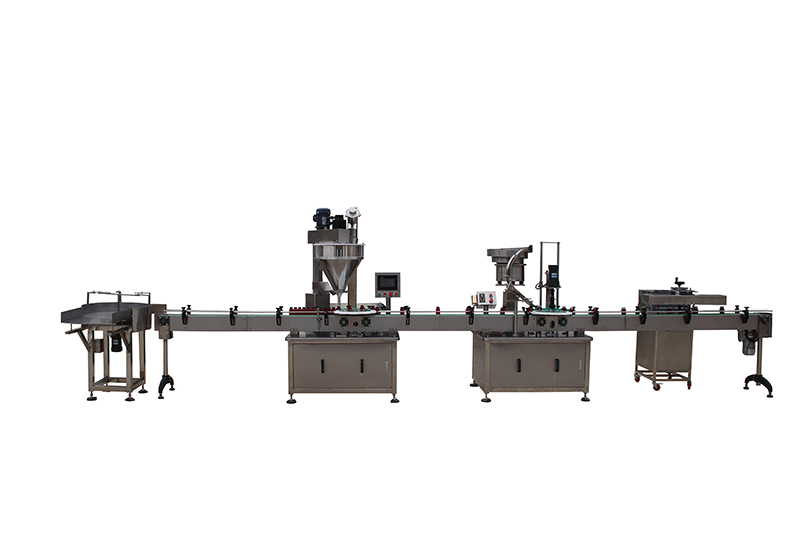

Automatic liquid filling machine machine

The machine is filled, plugged, locked and other processes.Mainly used for in-line production of large infusions and other small dose solutions,And can be equipped with a labeling machine to form an ideal production line.The production line design is reasonable, simple operation, easy to maintain, in full compliance with the new GMP requirements.

Machine features:

1.Automatic counting function with bottle deficiency and non filling.

2.Stable operation,small noise,accurate filling.

3.Filling system setting shrinkage function,no drop leakage. Suitable for all kinds of viscous liquid filling.

4.The filling head is filling at dive into the bottle, slowly rising to prevent foaming.

5.The exterior material is 304 stainless steel and conforms to GMP regulations.

6.It can be adapted to multi-standard production, and the filling adopts anti-drip valve body.

7.The bottle breaking rate is low, the qualified rate of the finished product is high, and the energy consumption is small. The entire production line can be controlled by stand-alone and interlocked.

Sample:

Sample:

| Applicable specifications | 20-500ml |

| Production capacity | 30-50 bottles / min |

| Filling accuracy | ≤±1% |

| Rotating (rolling) cover rate | ≥98% |

| Power supply | 380V/50Hz |

| Power | 3 kw |

| Weight | 700Kg |

| Dimensions | 2500 × 1100 × 1600 (mm) |