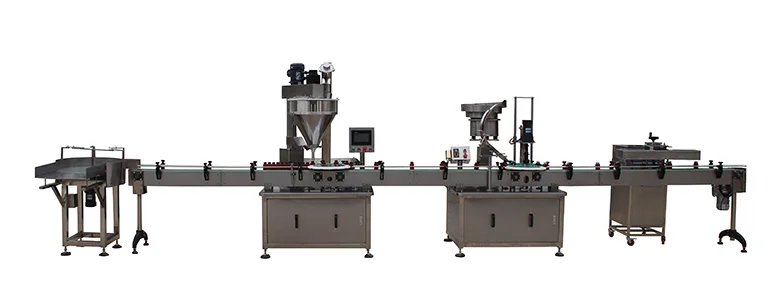

Bottle filling-Capper-Labbling-Coder packing line

Powder filling machine: The machine adopts the combination of screw filling and electronic weighing feedback, and is controlled by microcomputer. It has functions of automatic quantitative, automatic filling, automatic correction error, counting and clearing. Suitable for compound seasonings, natural seasonings, food additives, flavors and fragrances, flour, milk powder, protein powder, solid beverages, sugar, pesticides, veterinary drugs, washing powder, enzyme preparations, feed additives, chemicals, new building materials, etc. , ultra fine powder), quantitative filling and packing of powder mixture.

Powder filling machine: The machine adopts the combination of screw filling and electronic weighing feedback, and is controlled by microcomputer. It has functions of automatic quantitative, automatic filling, automatic correction error, counting and clearing. Suitable for compound seasonings, natural seasonings, food additives, flavors and fragrances, flour, milk powder, protein powder, solid beverages, sugar, pesticides, veterinary drugs, washing powder, enzyme preparations, feed additives, chemicals, new building materials, etc. , ultra fine powder), quantitative filling and packing of powder mixture.

Liquid filling machine:The machine is filled, plugged, locked and other processes.Mainly used for in-line production of large infusions and other small dose solutions,And can be equipped with a labeling machine to form an ideal production line.The production line design is reasonable, simple operation, easy to maintain, in full compliance with the new GMP requirements.

Technical Parameter:

Technical Parameter:

| Applicable specifications : | 20-500ml |

| Production capacity : | 30-50 bottles / min |

| Filling accuracy: | ≤±1% |

| Rotating (rolling) cover rate: | ≥98% |

| Power supply: | 380V/50Hz |

| Power : | 3 kw |

| Weight: | 700Kg |

| Dimensions: | 2500 × 1100 × 1600 (mm) |

Capping machine:This machine adopts inverter control, the transmission machinery applies cam principle, the disc splitter location, and the screw cap of the circular screw cap is implemented.

Technical Parameter:

| Number of screw bottle cap | one cap |

| Bottle cap size | 15-100mm |

| Bottle diameter | Φ35-Φ130mm |

| Bottle height | 50-320mm |

| Capping speed | 10-60bottles/min |

| Rated power | 1kw |

| Machine size | 150(L)*80(W)*160(H)mm |

| Weight | 280kg |

| Voltage | 220V,50/60hz,0.55kw |

Labeling machine:Put bottles into the conveyor belt, enter the separation mechanism, and after the separation mechanism separates these bottles, the bottle reaches the labeling position. The cylinder drives the soft silicone roller to clamp the bottle and drives it to rotate.In the appropriate time, the control system controls the corresponding motor to send the label and attach it to the position to be labeled, and is rotated and covered by the silicone roller. After the labeling is completed, the bottle is released and is continuously transported. The attaching action of a label is completed.

Technical Parameter:

Technical Parameter:

| Applicable bottle size | Diameter:30-150mm; height:30-250mm |

| Label length | 10-260mm |

| Label width | 10-160mm |

| Labeling speed | 0-60 bottles/min |

| Applicable label | Self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc. |

| Label roll size | Outer diameter<300mm; Inner diameter:76mm |

| Machine size | 2200(L)*1400(W)*1750(H)mm |

| Weight | 200kg |

| Working air pressure | 4-8Kg/Cm2 |

| Voltage | 220V,50/60hz,0.5kw |

Our Filling, Capping, packing and labeling Line including:

Bottle unscrambler,

Powder filling machine

Liquid filling machine

Capping machine

Sealing machine

Sticker Labeling machine

Shrink sleeve wrapping machine

Packing machine

Code printer machine

| Packing speed | 500-1500bottle/hour | Measuring range | 30-2000g |

| Power supply | AC380V 50Hz 0.9KW | Weight accuracy | ±3‰ |

| Machine size | (L)800×(W)800×(H)1960mm | Machine weight | 175KG |